Want To Start A Plastic Recycling Business At Your School Or Community Centre

There is money in waste, especially when you put the goggles of micro-factories on.

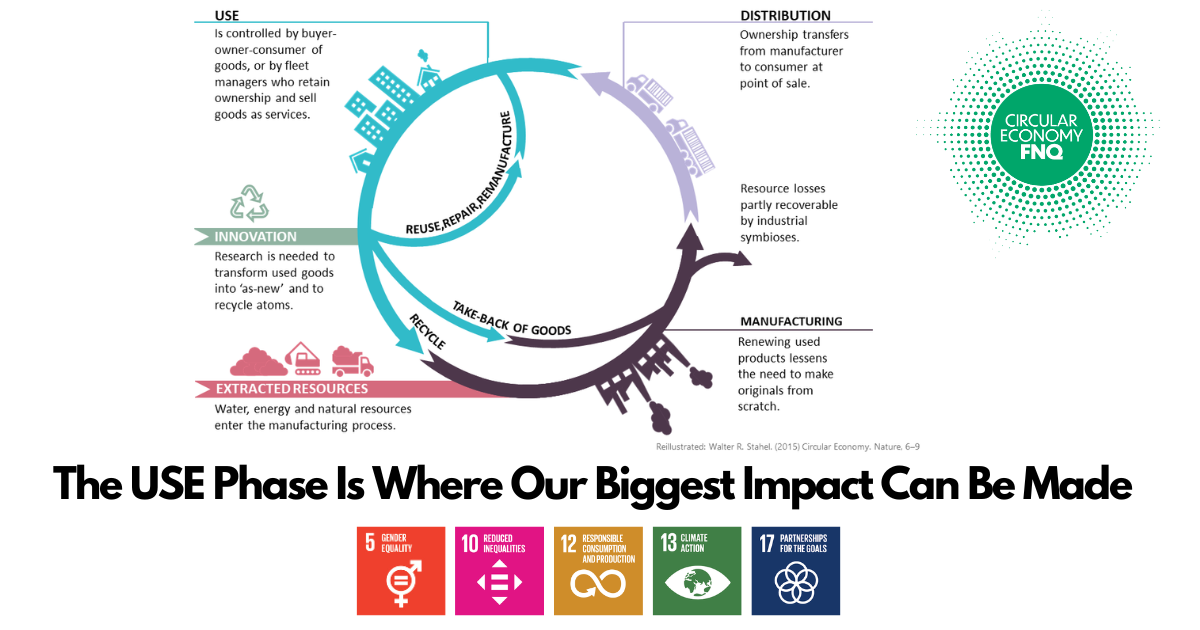

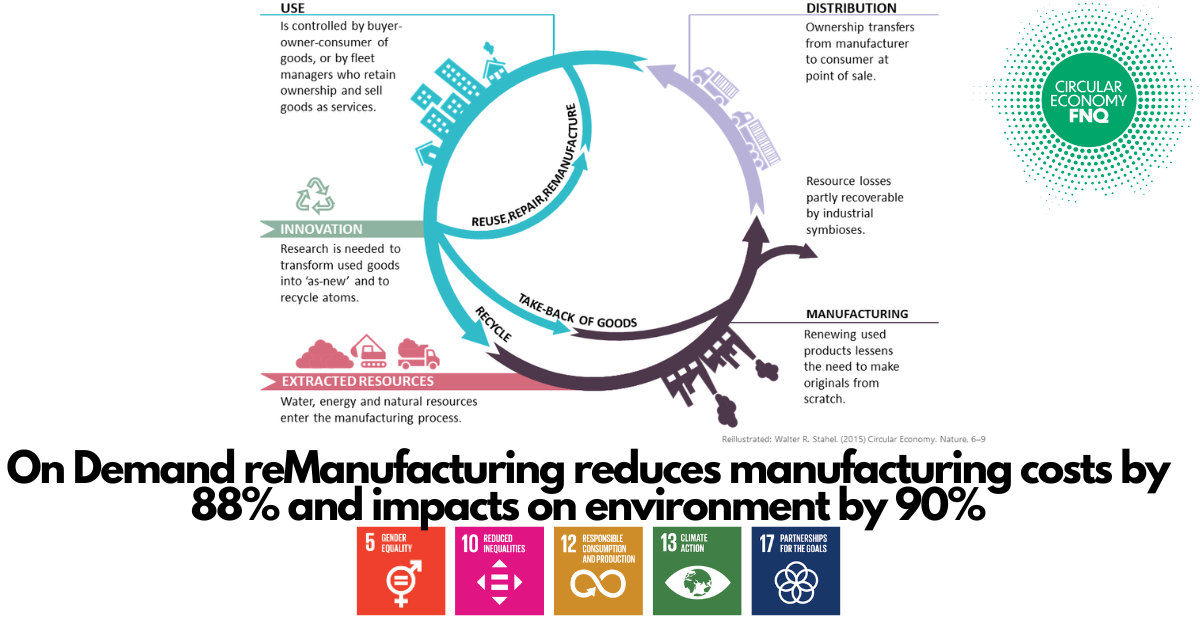

Walter R. Stahel is the grand father of the Circular Industrial Economy, the OG of Circular Economy Specialists.

This is his graphic above and he has strongly recommended the use of Micro Factories in regional and remote locations for the Innovation Phase - Reuse, Repair and Remanufacture stage.

A micro factory is a small-scale manufacturing facility that is designed to produce a specific product or range of products. These factories are typically smaller and more compact than traditional manufacturing facilities, and they are often used to produce smaller quantities of items, such as custom or niche products.

Micro factories can be used to produce a wide range of products, including in our case passive homes, bio char and bio oils that can be sold in the place they are processed. There are additive manufacturing units for plastics and metals, and from 2024 it can be used to take the end of life of products to supply brands with a Product Stewardship Certification.

This takes the 'away' of waste disposal out of the sole responsibility of the consumer and puts it on the producer.

When this is more widely adopted it will influence product design. If you are a high school student or a parent of one reading this, this is going to be an exciting green job for your kids.

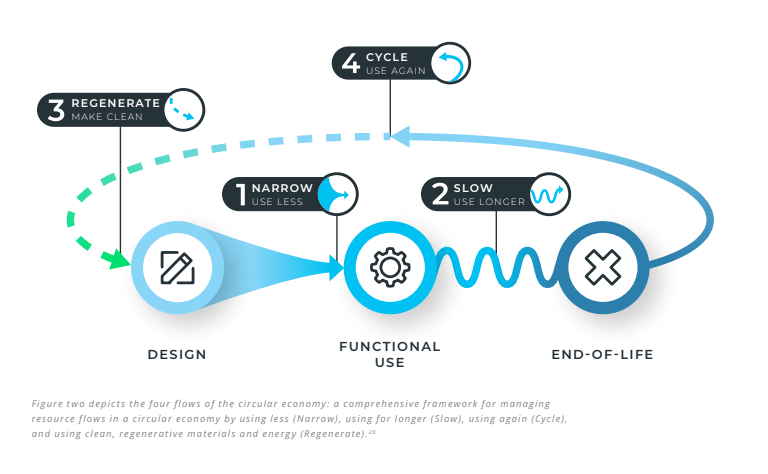

Micro factories, including the ones we have designed, often use advanced technologies such as 3D printing, CNC machines, and robotics to manufacture products quickly and efficiently. We have some innovation Ai data modelling that can develop predictive analysis from consumer and waste behaviour, a fantastic feedback tool for the Life Cycle Analysis - especially the USE phase.

Advantages of Micro factories include:

- Flexibility: Micro factories can be easily adapted to produce different products , and they can be quickly reconfigured to change production processes.

- Speed: Micro factories are often able to produce products more quickly than traditional manufacturing facilities, which can be beneficial for companies looking to get their products to market faster.

- Cost-effective: Micro factories can be more cost-effective than traditional manufacturing facilities, as they require less space and fewer resources.

- Local production: Micro factories can be set up in local communities, allowing manufacturers to produce goods closer to their customers and reduce the environmental impact of transportation.

- Customisation: micro factories have the ability to produce small batch, customised and personalised products which may not be feasible for large scale production.

Micro factories are still in a relatively early stage of development and it remains to be seen how they will impact the manufacturing industry in the long run.

The Lesson From Red Cycle - who's branding is still on packaging nearly 2 years later.

When the news that Red Cycle had issues with their key partner after a warehouse fire and that they were stockpiling their plastics. This wasn't a failure in a sense because we collectively managed to send in through Coles and Woolworths collection points 5000 Tonne soft plastics a week to them.

We want to be part of the solution. We just need a sustainable roadmap to follow.

We have one and a solution that will keep waste in place in Far North QLD and create Industry 5.0 jobs.

But what if we stopped moving waste from where it is and process it in place. That is where micro-factories come in for plastics,

the open-source solution designed Precious Plastics has a full suite of video training to help you understand how to sort and recycle plastics with their systems and we can niche it down into a few things.

Like recycle plastic lids/bottles into handles for kitchens or cupboards .

Knife handles for Caddy, Japanese knives, which had a hugely successful crowdfunded campaign.

Sadly though there is some bad news bubbling up about Precious Plastics, which is sad because over 500k micro businesses are making great products from it. Please do your own research and assessment but personally Circular Economy FNQ does not recommend it.

We do not endorse Precious Plastics because of the off gases in injection moulds done manually. We are starting to have feedback that more and more of these kinds of micro factories built on this system has health concerns which is why we have developed our own cluster of industrial micro factories.

How Schools Can Be Part Of The Solution

We have a need for 5 types of plastics for one of our printers.

HDPE, PP, PETG and ABS - every passive house we build we need 3 tonnes of it. If your school would like to be part of our supply chain we can invite excursion Advance Manufacturing Students into our Micro Factory to learn the CAD system to prototype other designs that have economic possibilities.

The other printer we have coming will take PET and HDPE and print with them without the need for sorting.

If you would like to be part of our supply chain for that and have the same opportunity to design something that is needed and has profit margin we are inviting Far North QLD schools to come in on excursions.

There is money in waste in fact there is an entire new economy in it and it will help us save the planet, lower the cost of living and make more business opportunities for those who are passionate about being part of the solution.

For an interactive educational toolkit for upper secondary high school educators and students to integrate circular thinking into the classroom, please click the link below.

It is for Teachers to download the workbooks and the educator support materials for in-class planning. Visit the educators’ hub for a range of extra resources that help to design incredible in-class learning around the Circular Economy.

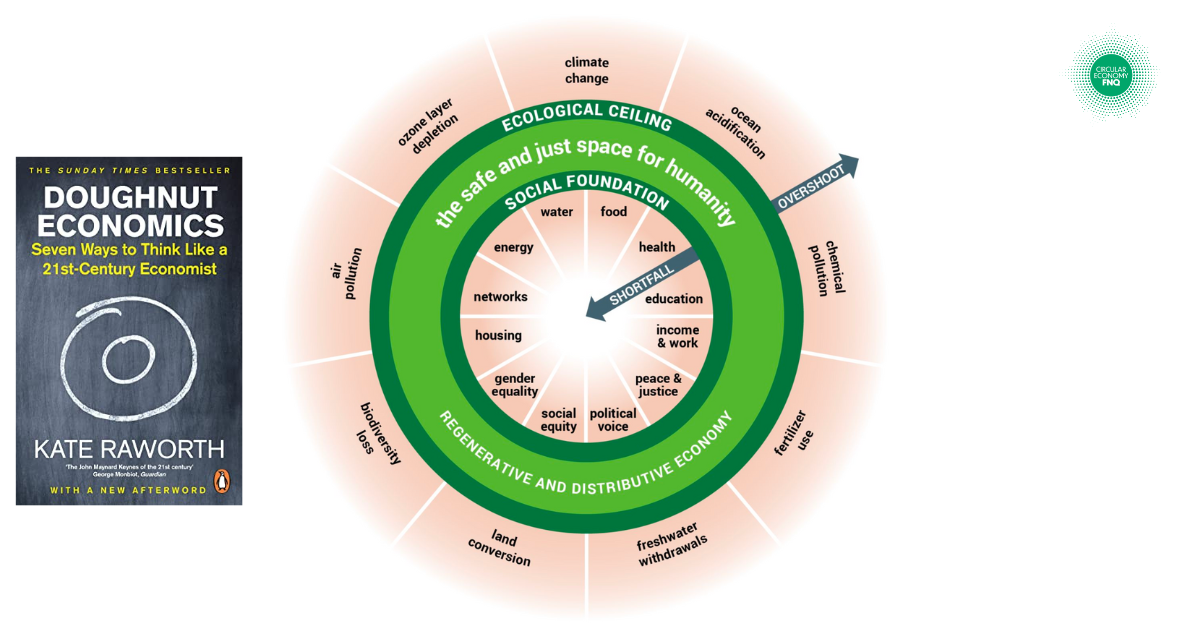

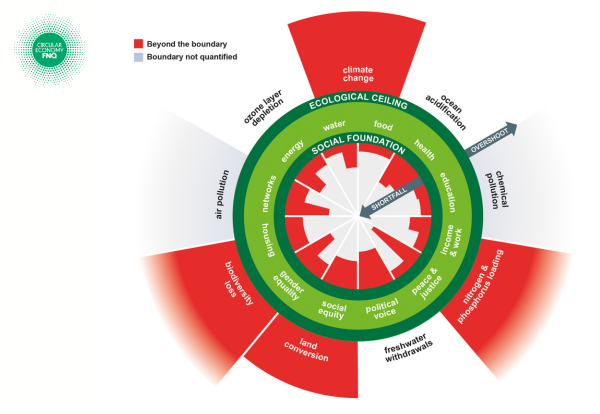

We like to blend Kate Raworths system thinking over Unschools, we find the two go exceptionally well together.

Enjoy this learning curve, you will see the world of systems so much clearer once you consume both the course above and this book below.

We look forward to future discussions with your team or school.